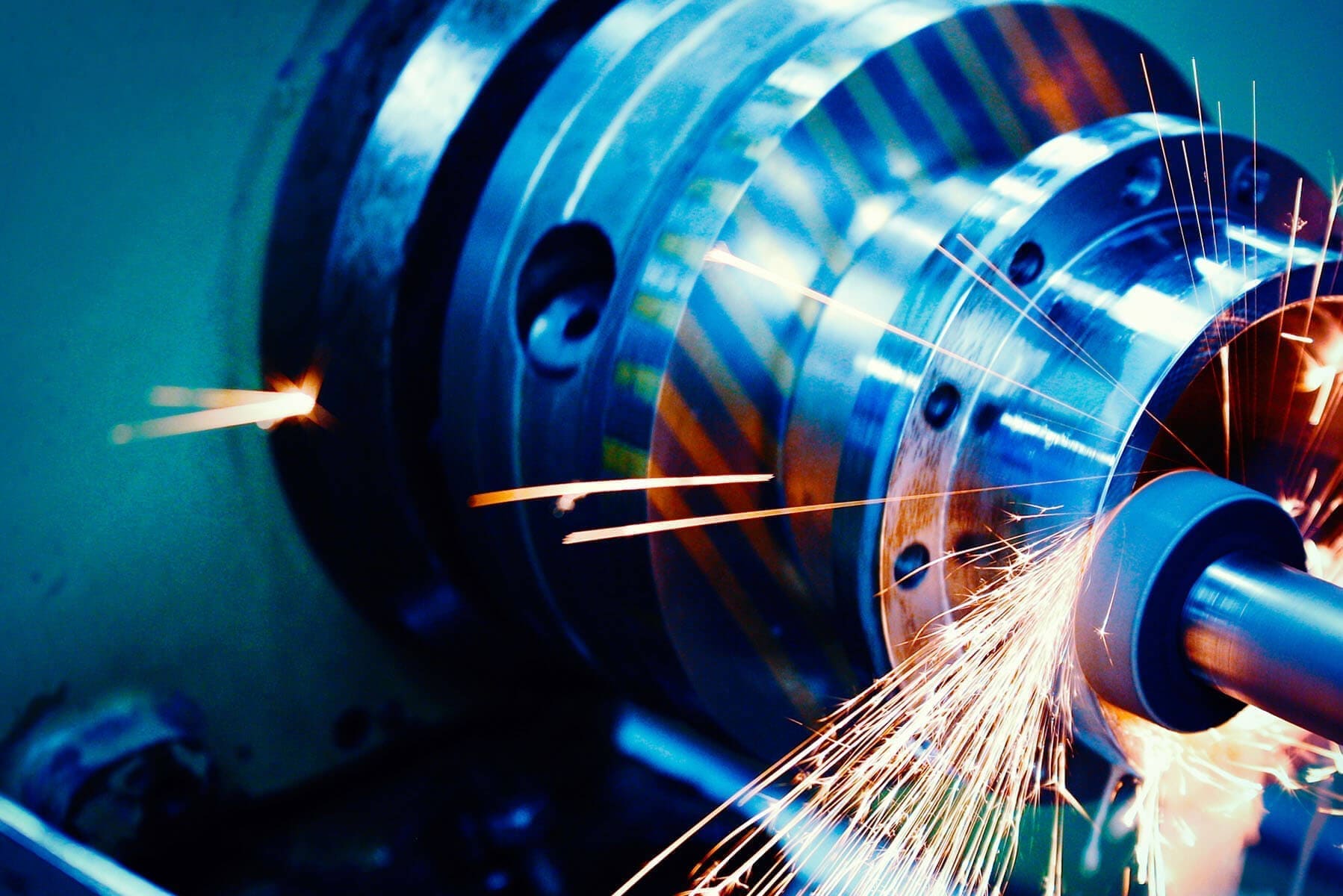

Embark on a journey of streamlined evacuation processes with Mechvac Technologies Pvt Ltd’s vacuum pumps, proudly manufactured in India. Our vacuum pumps are meticulously engineered to excel in vacuum evacuation applications, offering unparalleled performance, reliability, and efficiency. From creating vacuum chambers to removing air and gases, our vacuum pumps are the cornerstone of precise and efficient evacuation solutions across industries.

what is a vacuum Evacuation?

Vacuum evacuation refers to the process of removing air or other gases from a closed space or container to create a vacuum, which is a state of low pressure compared to the surrounding atmosphere. This process is commonly used in various industrial, scientific, and manufacturing applications for purposes such as:

Degassing: Removing gases or air bubbles from liquids or materials to improve their purity, stability, or performance. This is common in processes such as casting, resin impregnation, and chemical synthesis.

Leak Testing: Evacuating a sealed system to test for leaks or defects by observing pressure changes over time. This is crucial in industries where airtight seals are necessary, such as automotive, aerospace, and HVAC (heating, ventilation, and air conditioning).

Vacuum Packaging: Removing air from packaging containers or bags to extend the shelf life of perishable goods by reducing oxidation and microbial growth. This is widely used in food packaging and preservation.

Vacuum Furnaces: Creating a vacuum environment inside a furnace or chamber for processes such as heat treatment, brazing, or sintering. Vacuum conditions prevent oxidation and contamination of materials at high temperatures.

Vacuum Distillation: Evacuating a distillation apparatus to lower the boiling points of components and facilitate separation and purification processes. This is common in industries such as petrochemicals, pharmaceuticals, and food processing.

Semiconductor Manufacturing: Creating a vacuum environment in semiconductor fabrication processes to prevent contamination and ensure precise deposition and etching of materials.

Introducing the AX Dry Screw Series & MT Series, the top choice for vacuum evacuation applications. Engineered with cutting-edge technology and precision craftsmanship, the AX & MT Series offers a plethora of benefits that redefine vacuum evacuation processes:

MT Series benefits: –

Reduce Energy Consumption: The MT Series is designed with energy efficiency in mind, utilizing advanced technologies to minimize energy consumption during operation. This ensures cost savings on energy bills while reducing environmental impact.

Save on Maintenance Costs: With its robust construction and reliable performance, the MT Series requires minimal maintenance, resulting in cost savings over the system’s lifespan. Reduced downtime for maintenance translates to increased productivity and efficiency.

Maximize Operational Reliability: The MT Series is renowned for its unmatched operational reliability, providing continuous performance even in challenging degassing applications. Its durable components and advanced control systems ensure consistent operation, minimizing the risk of unplanned downtime.

Increase Production Output: By optimizing vacuum performance and efficiency, the MT Series enables faster processing times, allowing for increased production output. Its high-speed pumping capabilities ensure efficient degassing, contributing to overall throughput improvements.

Protect the Environment: Through reduced energy consumption and efficient operation, the MT Series helps protect the environment by minimizing carbon emissions and resource usage. By choosing the MT Series, you’re making a sustainable choice that aligns with environmental stewardship goals.

AX Dry Screw Series benefits:

Reduce Energy Consumption: Similar to the MT Series, the AX Dry Screw Series prioritizes energy efficiency, utilizing advanced dry screw technology to minimize energy consumption. This results in significant cost savings on energy bills and reduced environmental impact.

Save on Maintenance Costs: With its innovative design and robust construction, the AX Dry Screw Series requires minimal maintenance, leading to cost savings over time. Its self-lubricating mechanism eliminates the need for oil changes, reducing maintenance efforts and associated costs.

Maximize Operational Reliability: The AX Dry Screw Series offers exceptional operational reliability, providing continuous performance in demanding degassing applications. Its rugged construction and advanced control features ensure reliable operation, minimizing the risk of downtime and production interruptions.

Increase Production Output: By delivering efficient vacuum performance, the AX Dry Screw Series enables faster processing times, leading to increased production output. Its high-speed pumping capabilities facilitate rapid degassing, enhancing overall productivity and throughput.

Protect the Environment: Through energy-efficient operation and reduced maintenance requirements, the AX Dry Screw Series helps protect the environment by minimizing carbon emissions and resource usage. By choosing the AX Dry Screw Series, you’re making a sustainable investment that aligns with environmental conservation efforts.

MT Series images & AX Dry Screw Series