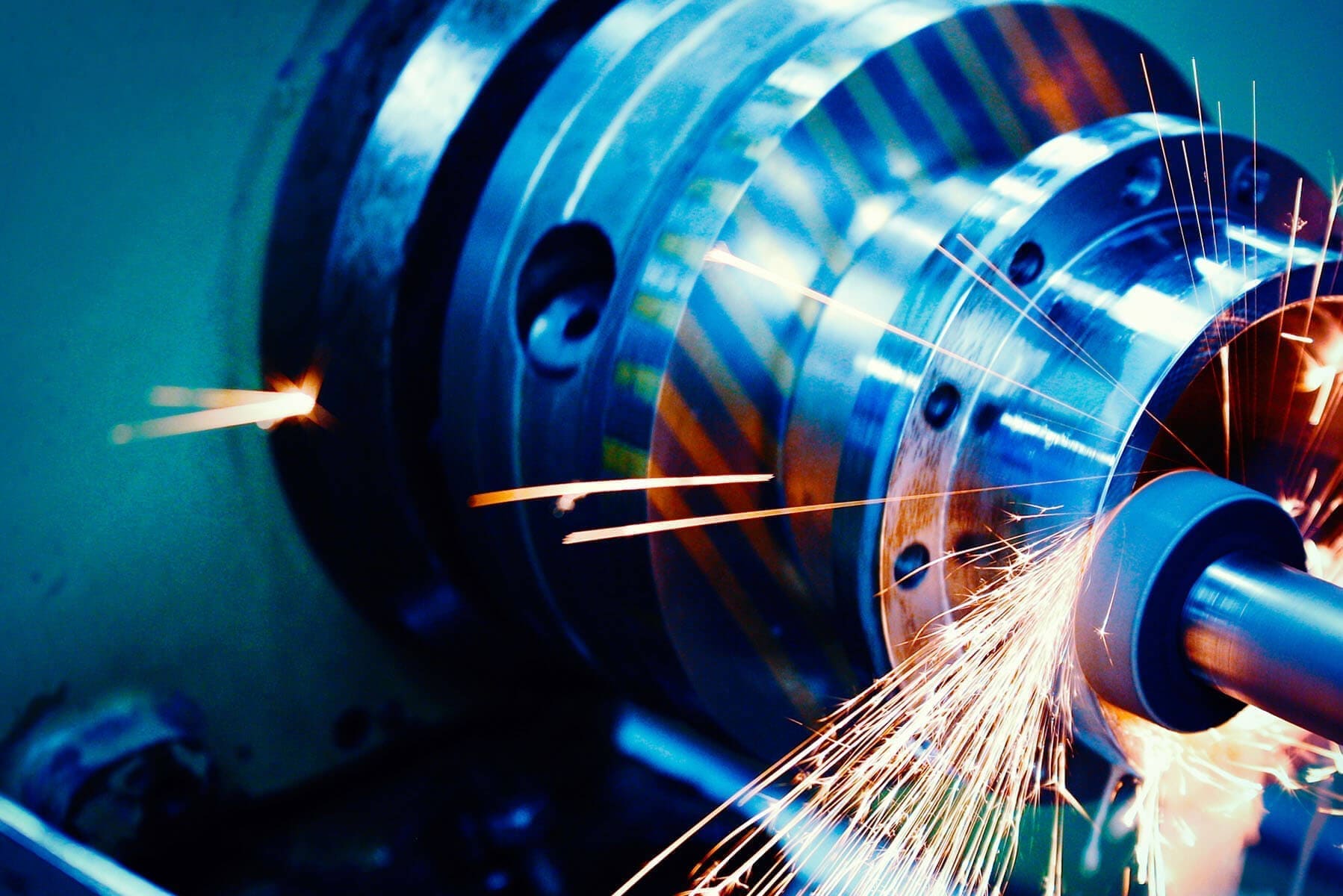

Enter the realm of efficient and precise drying solutions with Mechvac Technologies Pvt Ltd’s vacuum pumps, proudly manufactured in India. Our vacuum pumps are engineered to excel in vacuum drying applications, offering unparalleled performance, reliability, and versatility. From removing moisture to preserving product quality, our vacuum pumps are the cornerstone of efficient drying processes across industries

What is Drying Process?

The drying process is a method used to remove moisture or other liquids from a solid material, typically by exposing it to heat, air, or other drying agents. Drying is employed in various industries for purposes such as preserving food, reducing the moisture content of materials for storage or transportation, and preparing products for further processing or use.

Vacuum pumps are commonly used in drying applications where the removal of moisture needs to occur under low-pressure conditions. Here are a few scenarios where vacuum pumps play a crucial role in the drying process:

Vacuum Drying: In vacuum drying, the material to be dried is placed in a vacuum chamber where the air pressure is reduced below atmospheric pressure. This lowers the boiling point of water, allowing moisture to evaporate more rapidly from the material even at lower temperatures. Vacuum pumps create and maintain the required vacuum level in the chamber, facilitating efficient moisture removal.

Freeze Drying: Freeze drying, also known as lyophilization, is a process used to remove moisture from substances while preserving their structure and properties. In freeze drying, the material is frozen and then subjected to a vacuum, causing the frozen water to sublimate directly from solid to vapor without passing through the liquid phase. Vacuum pumps create and maintain the vacuum environment necessary for freeze drying to occur.

Evaporation Processes: Vacuum pumps are also used in various evaporation processes where liquid solutions or suspensions are dried by evaporating the solvent under reduced pressure. Examples include rotary evaporation, where a rotating flask containing the liquid is subjected to vacuum to promote faster evaporation, and thin-film evaporation, where a liquid film is heated and evaporated under vacuum conditions.

Introducing the MT Series, the optimal choice for vacuum drying processes. Engineered with precision and innovation, the MT Series offers a plethora of advantages that redefine your drying operations:

MT Series benefits: –

Reduce Energy Consumption: With cutting-edge technology and efficient design, the MT Series minimizes energy consumption during the drying process. By optimizing energy usage, it not only lowers operational costs but also promotes sustainability by reducing your carbon footprint.

Save on Maintenance Costs: Built for durability and longevity, the MT Series requires minimal maintenance, resulting in decreased downtime and substantial savings on maintenance expenses. Its robust construction and reliable components ensure hassle-free operation, allowing you to focus on your core tasks without worrying about frequent repairs.

Maximize Operational Reliability: The MT Series is synonymous with reliability, delivering consistent performance even in the most demanding drying applications. Its advanced features and high-quality engineering guarantee uninterrupted operation, minimizing the risk of disruptions and optimizing productivity in your facility.

Increase Production Output: By enhancing efficiency and reliability, the MT Series accelerates the drying process, leading to higher production outputs. Its superior performance streamlines material handling, reduces bottlenecks, and boosts throughput, enabling you to meet production targets with ease and efficiency.

Protect the Environment: Committed to environmental stewardship, the MT Series incorporates eco-friendly features that mitigate environmental impact and promote sustainability. By choosing the MT Series, you not only enhance operational efficiency but also contribute to a cleaner, greener future for generations to come.

MT Series images And Boosters