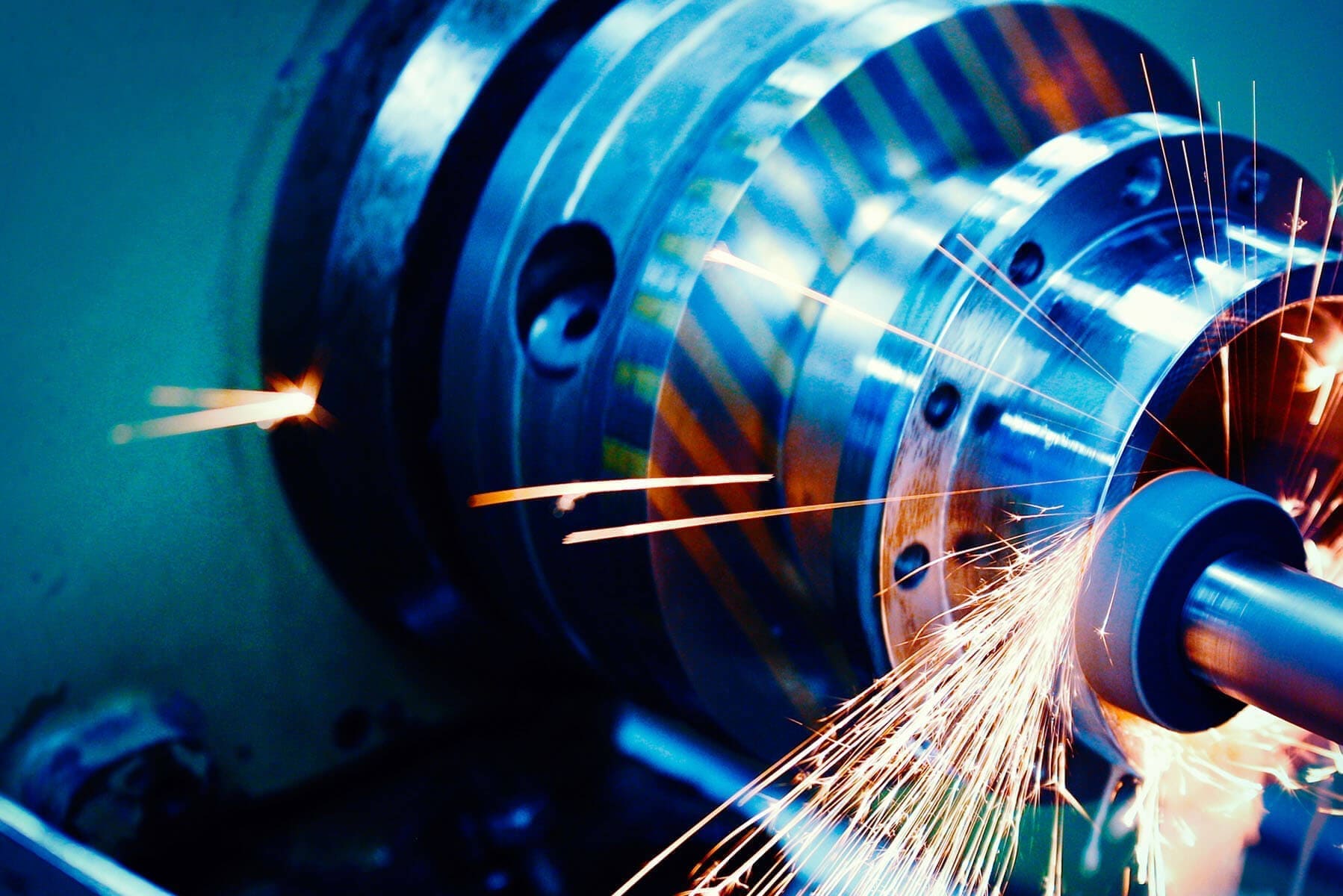

Enter the world of flawless surface coating with Mechvac Technologies Pvt Ltd’s vacuum pumps, proudly manufactured in India. Our vacuum pumps are meticulously crafted to excel in vacuum coating applications, offering unparalleled performance, reliability, and precision. From enhancing durability to improving aesthetics, our vacuum pumps are the foundation of seamless and precise coating processes across industries.

were we use vacuum in Coating processes?

Physical Vapor Deposition (PVD):

PVD is a coating process used to deposit thin films of materials onto substrates in a vacuum environment.

In PVD, a solid material, known as a “target,” is vaporized in a vacuum chamber using methods such as sputtering or evaporation.

The vaporized material condenses onto the substrate, forming a thin film coating.

Vacuum is essential in PVD processes to create a low-pressure environment, which minimizes the interaction of the vaporized material with air and ensures the purity and quality of the deposited coating.

Chemical Vapor Deposition (CVD):

CVD is another coating process used to deposit thin films onto substrates, but it involves chemical reactions between gases to form the coating material.

In CVD, precursor gases are introduced into a vacuum chamber and undergo chemical reactions on the substrate surface, resulting in the deposition of a thin film.

Vacuum is utilized in CVD processes to control the pressure inside the chamber, optimize gas flow, and prevent contamination of the deposited film.

Sputter Coating:

Sputter coating is a type of physical vapor deposition process where atoms or ions are ejected from a target material by bombarding it with high-energy particles (typically ions) in a vacuum.

The ejected material then deposits onto the substrate, forming a thin film coating.

Vacuum is crucial in sputter coating to create a low-pressure environment, facilitate the movement of ions, and prevent contamination of the deposited film.

Evaporation Coating:

Evaporation coating involves heating a material to its vaporization temperature in a vacuum chamber, causing it to evaporate and condense onto a substrate.

The evaporated material forms a thin film coating on the substrate surface.

Vacuum is essential in evaporation coating to create a controlled environment free from atmospheric gases, ensuring the purity and quality of the deposited coating.

Introducing the MT & AX Series, the ultimate choice for vacuum coating applications. Engineered with precision and innovation, the MT & AX Series offers a multitude of benefits that revolutionize the coating process:

MT Series benefits: –

Reduce Energy Consumption: The MT Series is designed with energy efficiency in mind, utilizing advanced technologies to minimize energy consumption during operation. This ensures cost savings on energy bills while reducing environmental impact.

Save on Maintenance Costs: With its robust construction and reliable performance, the MT Series requires minimal maintenance, resulting in cost savings over the system’s lifespan. Reduced downtime for maintenance translates to increased productivity and efficiency.

Maximize Operational Reliability: The MT Series is renowned for its unmatched operational reliability, providing continuous performance even in challenging degassing applications. Its durable components and advanced control systems ensure consistent operation, minimizing the risk of unplanned downtime.

Increase Production Output: By optimizing vacuum performance and efficiency, the MT Series enables faster processing times, allowing for increased production output. Its high-speed pumping capabilities ensure efficient degassing, contributing to overall throughput improvements.

Protect the Environment: Through reduced energy consumption and efficient operation, the MT Series helps protect the environment by minimizing carbon emissions and resource usage. By choosing the MT Series, you’re making a sustainable choice that aligns with environmental stewardship goals.

AX Dry Screw Series benefits:

Reduce Energy Consumption: Similar to the MT Series, the AX Dry Screw Series prioritizes energy efficiency, utilizing advanced dry screw technology to minimize energy consumption. This results in significant cost savings on energy bills and reduced environmental impact.

Save on Maintenance Costs: With its innovative design and robust construction, the AX Dry Screw Series requires minimal maintenance, leading to cost savings over time. Its self-lubricating mechanism eliminates the need for oil changes, reducing maintenance efforts and associated costs.

Maximize Operational Reliability: The AX Dry Screw Series offers exceptional operational reliability, providing continuous performance in demanding degassing applications. Its rugged construction and advanced control features ensure reliable operation, minimizing the risk of downtime and production interruptions.

Increase Production Output: By delivering efficient vacuum performance, the AX Dry Screw Series enables faster processing times, leading to increased production output. Its high-speed pumping capabilities facilitate rapid degassing, enhancing overall productivity and throughput.

Protect the Environment: Through energy-efficient operation and reduced maintenance requirements, the AX Dry Screw Series helps protect the environment by minimizing carbon emissions and resource usage. By choosing the AX Dry Screw Series, you’re making a sustainable investment that aligns with environmental conservation efforts.

MT Series images & AX Dry Screw Series