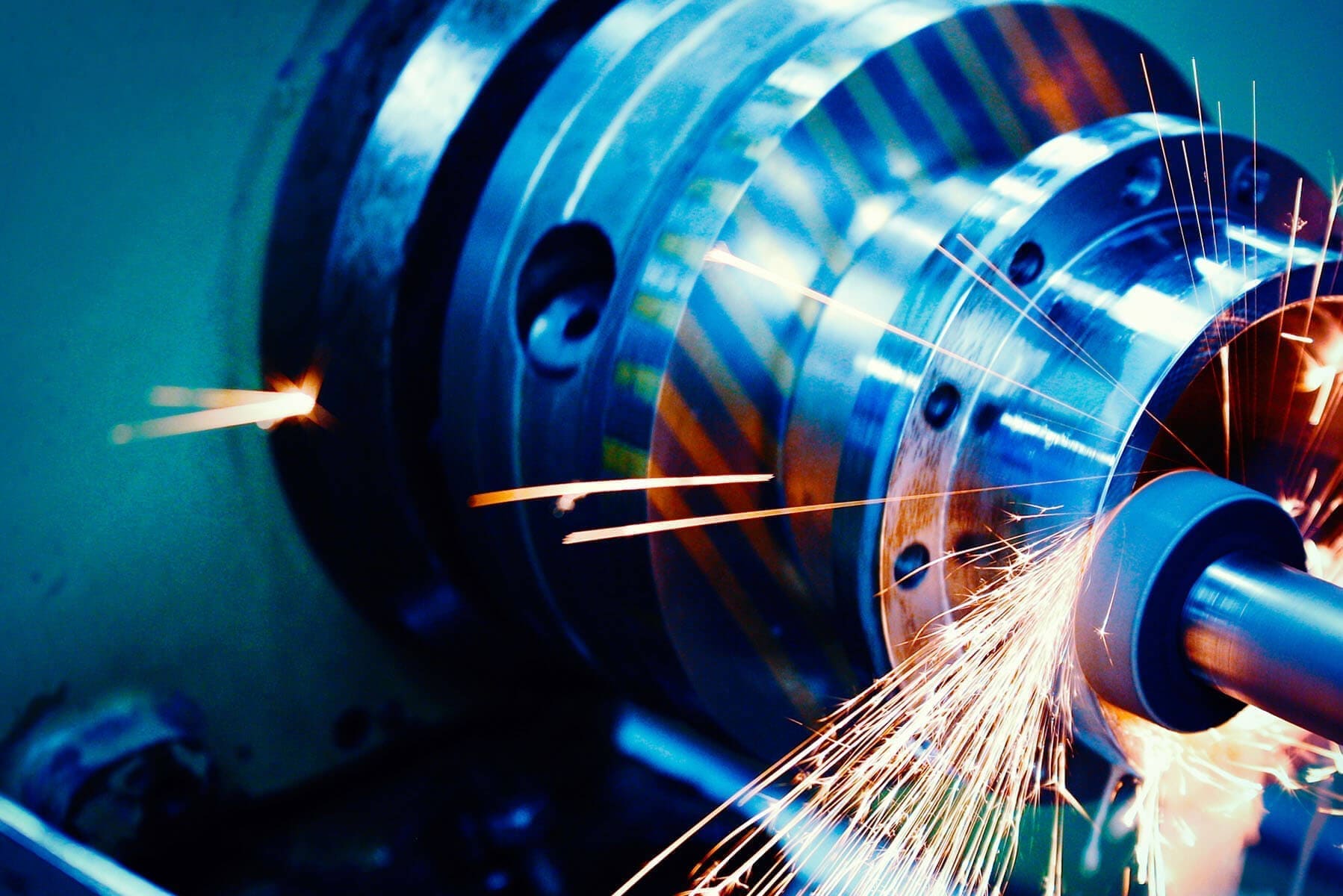

Step into the realm of advanced distillation techniques with Mechvac Technologies Pvt Ltd’s vacuum pumps, proudly manufactured in India. Our vacuum pumps are meticulously engineered to excel in vacuum distillation applications, offering unmatched performance, reliability, and efficiency. From refining chemicals to purifying solvents, our vacuum pumps are the cornerstone of precise and efficient distillation processes across industries.

what is vacuum Distillation processes?

Vacuum distillation is a process used to separate and purify components of a mixture with high boiling points, such as certain chemicals, solvents, or oils, by reducing the pressure within the distillation apparatus. This reduction in pressure lowers the boiling point of the components, allowing them to vaporize and be collected separately, based on their differences in volatility.

Here’s how vacuum distillation typically works:

Setup: The mixture to be distilled is placed in a distillation flask or vessel equipped with a heating source, such as a heating mantle or a steam jacket. A fractionating column may also be used to enhance separation efficiency.

Reduction of Pressure: Unlike traditional distillation, where the mixture is heated at atmospheric pressure, vacuum distillation involves reducing the pressure inside the distillation apparatus using a vacuum pump. By lowering the pressure, the boiling points of the components are reduced, enabling them to vaporize at lower temperatures.

Heating and Vaporization: The mixture is heated, typically using a heating source such as steam or an electric heater. As the temperature rises, components with lower boiling points vaporize first. The reduced pressure allows even high-boiling components to vaporize without undergoing thermal degradation.

Separation: The vaporized components rise through the fractionating column, where they undergo partial condensation and re-vaporization. This process helps to separate the components based on their differences in boiling points and volatility. The vapours are then collected and condensed into separate fractions.

Collection and Purification: The condensed fractions are collected in receivers and further processed to remove any remaining impurities or contaminants. This may involve additional distillation steps or other purification techniques to obtain the desired purity level.

Introducing the AX Dry Screw Series, the premier choice for vacuum distillation processes. Crafted with precision engineering and innovative technology, the AX Series offers a myriad of advantages that redefine your distillation operations:

Reduce Energy Consumption: With cutting-edge energy-efficient design, the AX Dry Screw Series minimizes power consumption during distillation processes. By optimizing energy usage, it not only reduces operational costs but also promotes environmental sustainability by lowering carbon emissions.

Save on Maintenance Costs: Engineered for durability and longevity, the AX Dry Screw Series requires minimal maintenance, resulting in reduced downtime and substantial savings on maintenance expenses. Its robust construction and reliable components ensure uninterrupted operation, allowing you to focus on productivity without worrying about frequent repairs.

Maximize Operational Reliability: The AX Series sets the benchmark for reliability, delivering consistent performance even in the most demanding distillation tasks. Its advanced features and high-quality engineering guarantee dependable operation, minimizing the risk of disruptions and optimizing productivity in your facility.

Increase Production Output: By enhancing efficiency and reliability, the AX Dry Screw Series accelerates distillation processes, leading to higher production outputs. Its superior performance streamlines operations, reduces cycle times, and boosts throughput, enabling you to meet production targets with ease and efficiency.

Protect the Environment: Committed to environmental stewardship, the AX Series incorporates eco-friendly features that minimize environmental impact and promote greener practices. By choosing the AX Dry Screw Series, you not only improve operational efficiency but also contribute to a cleaner, more sustainable future for generations to come.

AX Series images